DER NICOLAY-SPO2-SENSOR MACHT ALLES ETWAS LEICHTER

So leicht hätten Sie es auch gern?

Treten Sie mit uns in Kontakt

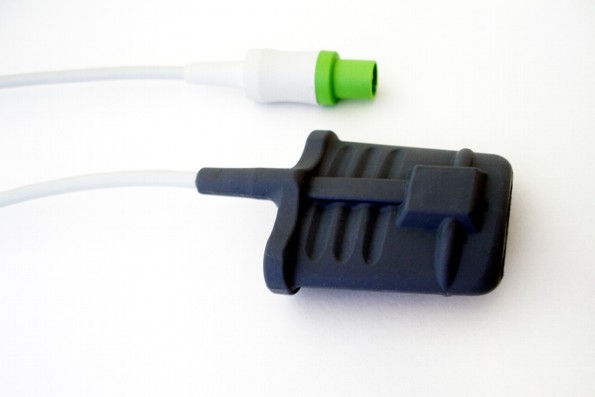

NICOLAY-SpO2-Sensor

Sehr robust und lange haltbar

Ihr Kundennutzen

- Sie erhalten eine komplette Lösung von Patient zu Gerät aus einer Hand

- Sie profitieren von geringen Werkzeugkosten durch Standardmodule

- Sie bekommen für Ihre spezielle Applikation und zum Schutz Ihres Ersatzteilgeschäfts eine individuelle Ausführung durch:

o die Kalibrierung – die Auswahl der optischen Bauteile bestimmen Sie selbst

o die individuelle Anpassung und Adaptierung des Gerätesteckers

o das exklusive Labeling und die individuelle Farbgebung

NICOLAY-Finger-/Ohrpulssensor

Für Kardioanwendungen

Immer wieder werden wir gefragt: Was heißt Spo2 oder auch SpO2? Oder auch: Was bedeutet SpO2 überhaupt? O2 steht natürlich für Sauerstoff. „Sp“ steht für die partielle Sauerstoffsättigung im Blut. Es geht also um Fragen wie diese: Wie hoch ist die Sauerstoffsättigung des Blutes? Wie hoch soll die Blutsauerstoffsättigung sein? Wie niedrig darf sie sein? Welcher SpO2-Wert ist angemessen für Neugeborene, für Kinder und für Erwachsene? Ermittelt wird der Wert mittels Pulsoxymetrie, die als nichtinvasives Standardmonitoring von Patienten im Rettungsdienst, auf Intensivstationen oder in der Anästhesie zum Einsatz kommt. Ein weiteres Anwendungsgebiet ist zum Beispiel auch die Schlafmedizin. Hier dient die Bestimmung der Sauerstoffsättigung des Blutes zur Diagnose, ob Erwachsene an Schlafapnoe leiden und wie sich dieses gesundheitliche Problem auf den Sauerstoff im Blut auswirkt.

Silikon und Sensorik

Darauf verstehen wir uns